Farming

The plant Coffea arabica or coffee is an understory perennial tree-shrub. When I took over the farm management in 1993, 90% of the trees were from the Borbón variety (Bourbon), and the rest are from the Pacas variety. Both of these varieties need to grow under a canopy of emergent trees. During the subsequent years, I been phasing out any other varieties of coffee trees in favor of the Borbón because in my opinion this variety has the smoothest taste of any coffee tree.

The farming of the coffee is divided in dry (mid November to April) and rainy (May to November) season activities. These activities are the “Agricultural” work that happens mostly during the rainy season and the “harvest” that happens during the dry season.

In the farm the flowering of the plants start in mid February and finishes by May; the bulk of the harvest comes from the flowering that comes at the middle of April and May.

There is a different set of activities during the “agricultural” phase, such as:

There is a different set of activities during the “agricultural” phase, such as:

Pruning the coffee trees after the harvest, fertilization, pruning the shade trees, control of weeds and control of insects that damage the coffee beans.

A common pest: “Broca de Cafeto”

Coffee berry borer

Hypothenemus hampei Ferr Coleoptera

One basic element in all our agricultural activities is the ZERO use of pesticides, fungicides and herbicides in our production. Also, we maintain a diverse array of canopy trees, directed not only for the shade of our coffee, but also to provide habitat for different species of animals.

It is my contention that treating the coffee not as a “plantation,” but like the basis of a “Coffee Forest Ecosystem,” would ensure us long-term benefits that cannot be measured in money.

HARVEST

Now, when the harvest season comes, you find that on the same branch you have all the ranges of ripeness. The quality coffee must be picked and sorted by hand because in order to pick only the completely ripe cherries, there is no other method. Otherwise, you include the green cherries or unripe cherries that had not completely metabolized the caffeine molecule. In those beans the chlorogenic acid is prevalent, and this gives the coffee a particular astringent taste. In order to hide it, the commercial coffee houses over roast the beans. But these beans still can be identified by the bitter caustic aftertaste which is completely different from the clean low acidity present in those beans from cherries that achieve their peak maturation.

1-Green Cherries. 2-Unripe cherries. 3-Completely ripe cherries

After picking, the coffee must be processed immediately to prevent the fermentation caused by the juices that surround the beans inside the cherry.

The removal of the beans from the cherry is accomplished by mechanically splitting the cherry (inside each cherry there are two beans) by using a PULPERO (A machine that removes the pulp or skin of the cherry from the beans).

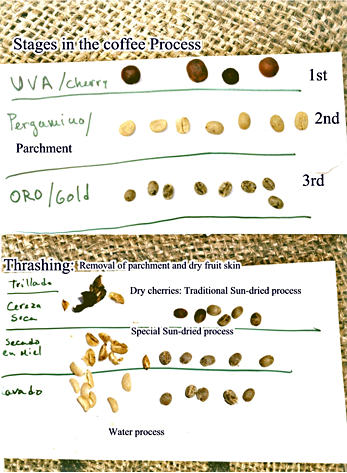

We make two types of processes: Water and Sun-dried.

For the Water Process we rinsed off the juices with water.

Afterwards, we put the coffee beans (in the parchment form) to dry, first, on ‘screen beds’ for 24 to 48 hours, and then we spread the coffee on the yards where they continue the drying process until the bean inside the parchment gets a humidity close to 12%. This process can take between 2 to 3 weeks.

For the Sun-Dried process, we prevent the fermentation by thinly spreading the coffee beans (in the parchment form) on the ‘screen beds,’ and we let them dry completely until the bean inside reaches a level of humidity close to 12%. This process takes a longer time to dry than the Water-process because the juices permeate the parchment; during the day the beans dry, but those dry juices regain humidity with the moist night air. Eventually, the drying of the beans takes between 5 to 8 weeks, depending of how many foggy afternoons you have during this period.

After the beans are dried, the next step in the production is the removal of the ‘parchment’.

We use a modified “corn grinder”, that cracks the parchment, and releases the bean.

Then we proceed to separate the beans from the loose parchment. Afterwards we sort the beans and remove all the beans that show imperfections, such as insect damage, malformed or broken beans.

Then, we sort the beans by size in order to prepare for the roasting process. Roasting together big and small beans affects the quality of the coffee because there is no uniformity in the level of roasting.

The beans are put in 150 lb bags, and then are taken to the roasting company Quality Grains S.A. Where the beans are roasted according to our instructions.

All of this work is done with a basic team of 7 people, headed by my manager (since 1997) Salvador Rivas Ortiz.

During the harvest, we hired 25 to 40 extra people depending on the volume of coffee to be picked.

ROASTING

The roasting is the last but not the least part in the process of the coffee. I pay for the roasting of my coffee to the Quality Grains roasting company, I work closely with the master roaster and have deviced 4 levels of roasting for the Water processcoffee and two levels for the Sun-dried process.

The roasting is done using the Agtron© Scale, developed for the Agtron company. The number in the scale refers to the percentage of light reflected from the surface of the coffee: a darker roast will reflect a minor amount of light than a lighter roast. This system has been adopted by the SCAA (Specialty Coffee Association of America) as the industry standard for gourmet coffees. I first learned about this system by working with Quality Grains, and it is very useful because there is a consistency in how the coffee is roasted.